Doha, Qatar

Zone 81, New Industrial Area

Saturday - Thursday - 7 AM - 5 PM

Sunday Closed

+974 44430780

info@uconqatar.com

Zone 81, New Industrial Area

Sunday Closed

info@uconqatar.com

Supply & Fabrication

We Ucon Metal Industries recognized as one of the reputed and reliable manufactures and suppliers of Fabricators of steel grating Panels, Stair threads, Hand Rail System, Cage ladders, Panel Clips, SS/GI Grating Clamps, Step Iron, Stud Products and more.

Powered by modern manufacturing facilities and a strong team of experienced professionals we assure high-quality products. No wonder, our products are widely used in many different industries such as oil and gas, power, water, mining and construction

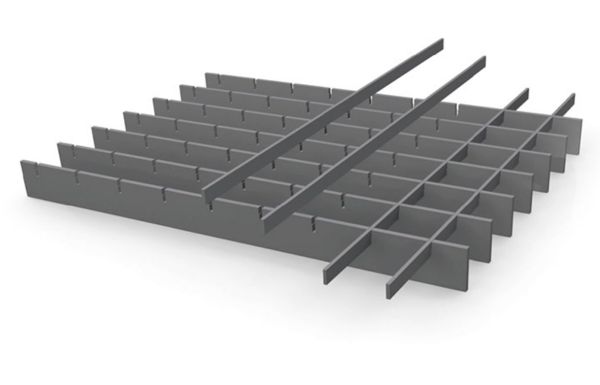

Electro Forged Type Gratings Electro forged grating can be defined as a series of metal bars positioned verticaly, placed an equal distance apart and joined by cross members by passing high current (2500 KVA) Simultaneously very high hydraulic pressure will be applied to forge weld these together rectangular pattern.

Load bar depths: 25, 30, 32, 35, 38, 40, 45, 50, 60 are most common. But we can produce upto 100mm

Load bar thickness: 3, 4, 5, 6 and 8mm

Panel size: 1000 x 6000 mm / 905 mm x6000 mm. (banded or un banded)

Load bar type: Plain or Serrated

Cross bar size: Twisted square bar in 6mm /8mm/I0 mm

Pitches: 30×100, 41×100, 30×50, 41×50,34×38

Finish: Self-color / Hot Dip Galvanized.

Ucon metal Press lock gratings ore made by notching the load-bearing bars and then interlocking with crossbars at very high pressure. These types of gratings are made from mild steel, stainless steel and aluminum materials.

Load bar depths: 25, 30, 32, 35, 38, 40, 45, 50, 60 upto 150mm

Load bar thickness: 3, 4 5,6,8 and 10mm

Cross bar depth: 10, 20, 25, 30 & 40

Load bar/Cross bar type: Plain or Serrated

Cross bar thickness: 3,4 & 5 mm

Finish: Self Color or Hot Dip Galvanized as per ASTM 4123/ BS 729 Table 1

Material: ASTM A36/ ASTM 41011. & BS EN 10025 S275JR

Heavy Duty Gratings manually Welded Heavy Duty Gratings are designed to meet the need for gratings subject to heavy rolling and static loads such as highways, plant floors, loading docks, inlet covers, and airports. Since these conditions can range from light-duty forklifts to semi-trucks and trailers carrying maximum allowable highway loads.

Load bar depths: 35, 40, 45, 50, 60 upto 150 mm

load bar thickness: 5, 6, 8,10 and 12mm

Cross bar: Shall be Round Bars or Flat Bars or Square Bars to suit the application

Load bar type: Plain or Serrated

Finish: Self Color or Hot Dip Galvanised as per ASTM Al23. 8S.

Material: ASTM A36/ ASTM A1011. & BS EN 10025 S275JR

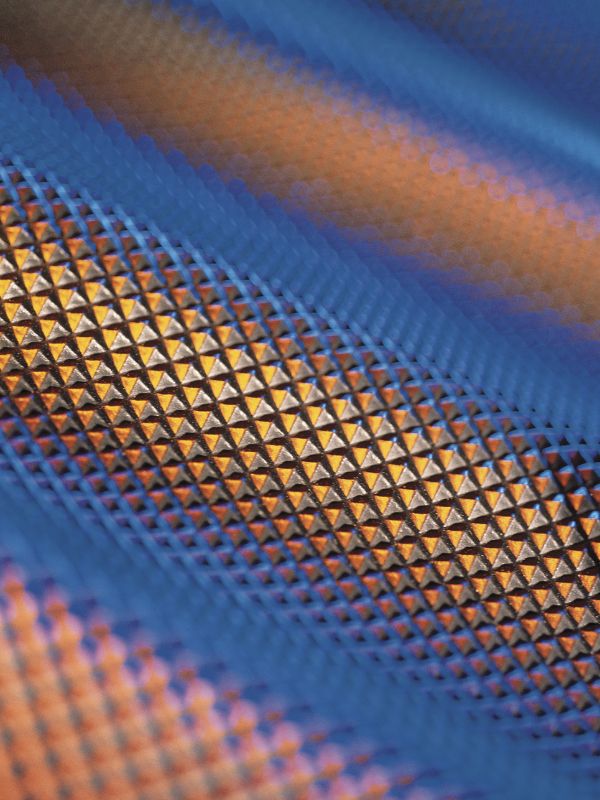

Ucon Metal Steel Stair Treads are made from Electra forged Steel Gratings with an Anti-slip Nosing Bar at the front edge Plus End Plates with Drilled / Slotted Holes on the Sides which will allow for Bolting to Stair Stringers.

Stair treads con be AAA icatou and supplied with any combination of load Bearing Bars and Mesh Sizes

All Treads are custom fabricated to meet various clients Size, Width and Length Specification

Treads shall be supplied with Anti Slip Pyramid Type / Liongrip Nosing , Durbar nosing. Chequered Plate Nosing and with Perforated blank Nosing

Tailor Mode End Plates are manufactured with Specific Drilled / Slotted hole Size and locations

As an option Stair Treads con be manufactured without end plates as well

Available in Self colour, Pointed and Not Dip Golvonsied Finishes

Ucon Metals Steel Stair Treads ore Sate, Self Cleaning, Skid Resistant. Cost effective, Durable, and ensures maximum visibility with easy installation.

Ucon Metal can offer Solutions based on your applications, the grating specification and

choices are the same as above, but the grating panels are fabricated and supplied as per client’s project requirements.

Durability, quickness, and ease of use are the three pillars that have made Ucon Metals grating fixing clamps the number one choice in every trade. We offer a cost-efficient process of clamping through our standard grating clamps available on quick delivery.

Ucon Metal supplies the Grating Fixing Clamps in Mild Steel, Hot Dip Galvanized Finish (Suitable for Fixing Mild Steel Galvanized Gratings) & Stainless steel AISI 304 OR 316 CLAMP (Suitable for Fixing S.S., AI., and FRP/GRP Gratings).

Ucon Metal can offer Solutions based on your applications, the grating specification and choices are same as above, but the grating panels are fabricated and supplied as per client’s project requirements. (exactly as per drawings). Toe plates / kick plates, nosing shall be welded to the gratings as per client drawings.

Looking for reliable engineering solutions and top-quality products for your projects? We’re here to help! Contact us to discuss your requirements, request a quote, or learn more about our wide range of services.

See why industry leaders trust Beconfab for durable, high-quality products and exceptional service. From mid-hinged poles to grating panels, our commitment to excellence supports projects across vital sectors in the Gulf.

Working with Beconfab has been a game-changer for our operations. Their mid-hinged poles and custom steel grating solutions have consistently met our high standards for durability and quality. The ease of installation and maintenance has significantly reduced downtime, and their customer service is always responsive and professional.

Beconfab's products have proven to be incredibly reliable for our water and power projects. We’ve used their grating panels and handrail systems extensively, and they’re built to withstand harsh conditions without compromising on quality. Beconfab has truly been a dependable partner for us & highly recommend to others.

We have trusted Beconfab for our lighting and structural needs on various projects, from industrial sites to suburban areas. Their mid-hinged poles have made maintenance so much easier, and the quality of their materials ensures we get long-term value. Highly recommend Beconfab for any kind of project from small to very large

P O Box: 37312, Street No.3, Building No. 217, Zone 81, New Industrial Area, Doha, Qatar

Tel : +974 444 30780

info@uconqatar.com

Beconfab, Qatar - All Rights Reserved